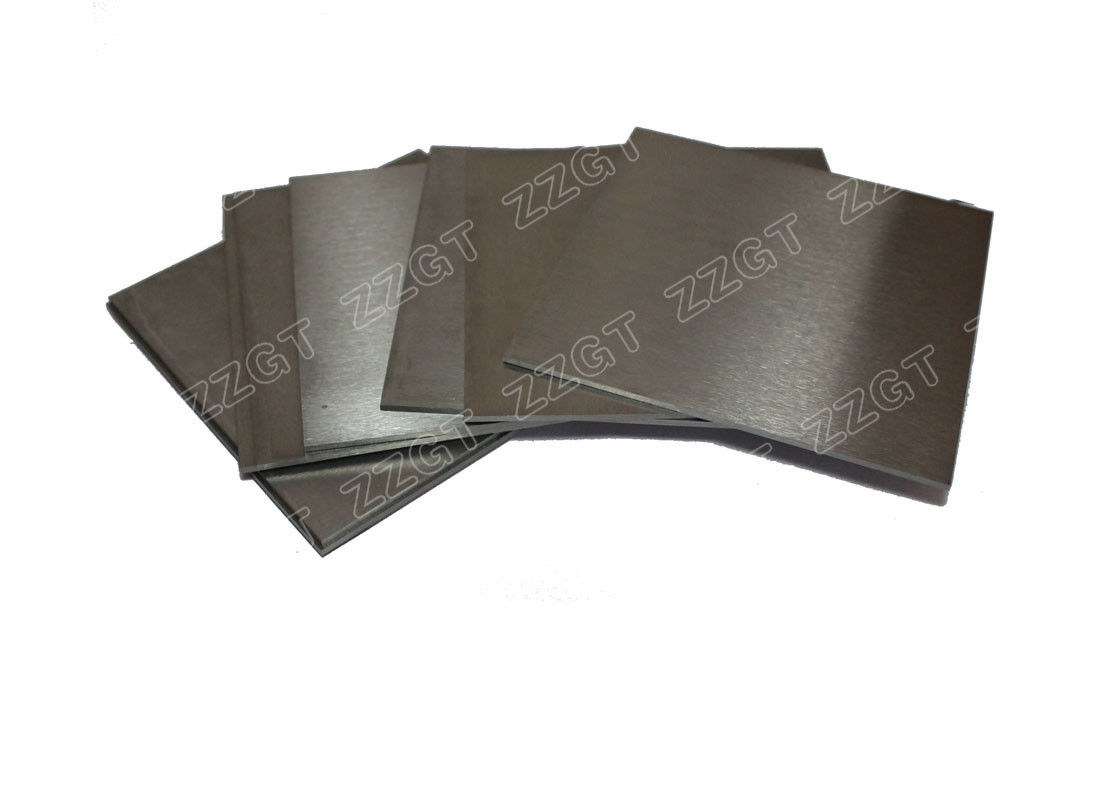

Ground K10 K15 K20 K30 K40 G40 Tungsten Carbide Draw Plate

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | ZZGT Li |

| Certification: | ISO9001:2015 |

| Model Number: | 100x100x1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Samples are accepted |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Paper box , Wooden Carton or Customized accepted |

| Delivery Time: | 7-15days |

| Payment Terms: | L/C, D/A, T/T, Western Union, MoneyGram |

| Supply Ability: | 400T/year |

|

Detail Information |

|||

| Material: | Virgin Tungsten Carbide | Grade: | YG15 |

|---|---|---|---|

| Surface: | Ground | Application: | Cutting Tools |

| Service: | 24hours | OEM: | Accepted |

| High Light: | G40 Tungsten Carbide Draw Plate,K40 Tungsten Carbide Draw Plate,K30 tungsten carbide drawplate |

||

Product Description

Ground K10 K15 K20 K30 K40 G40 Tungsten Carbide Draw Plate

K10 K15 K20 K30 K40 G40 Tungsten Carbide Draw Plate

As for grinding plate, below are the general features for your reference. For more details of specific type, please inform us.

1) Hard metal sheet is suitable for the production of various types of motors, electronic progressive dies and punches;

2) Various grades and types, the carbide plates have good versatility;

3) Cemented carbide plates have advantage of strict tolerance, flatness and surface smoothness.

4) Good wear resistance and impact resistance, long life time.

Grade Performance

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| GT55 | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |

More Details:

![]()

Factory Equipments:

There are some advanced producing equipments in Zhuzhou Gingte Cemented Carbide Co.,ltd

* HIP sintering furnace

* Spraying Draying system

* 200T TPA acutomatic press machine

* CNC Grinder

* Spark Erosion machine

* Wire cutting machine,etc

![]()

Contacts:

For further question, pls contact our sales engineer

Name:Daisy Tian

E-mail: zzgt3@gtcarbide.com

Whatsapp/Mobile:+8613874120766