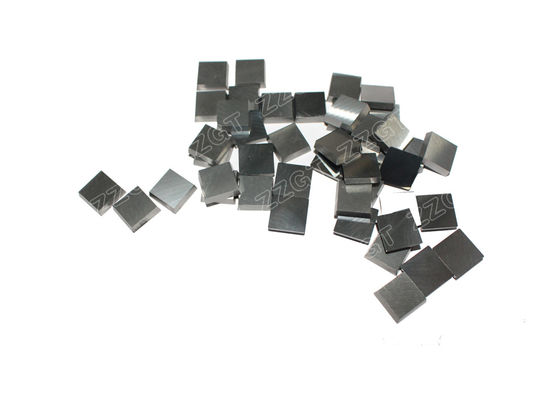

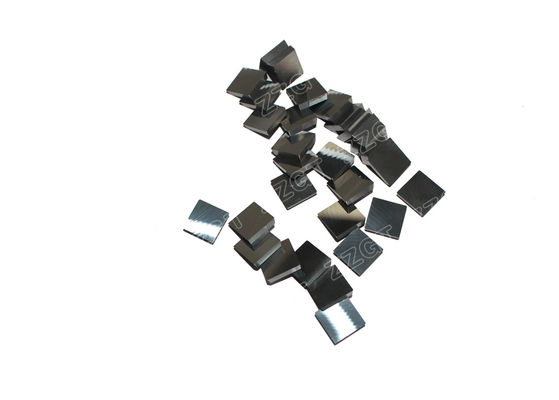

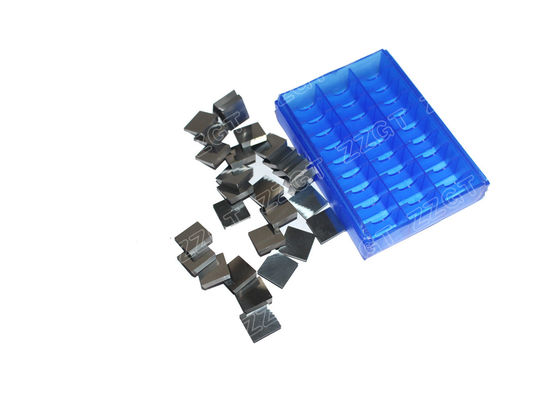

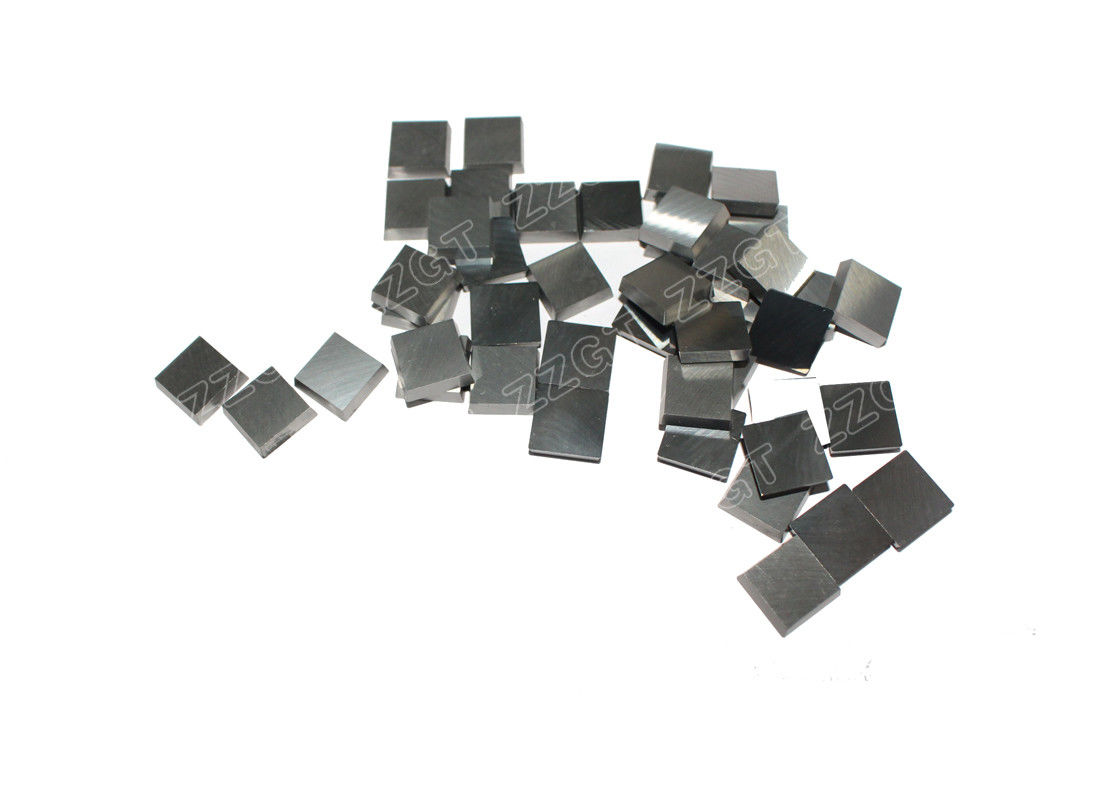

K20 P20 4130511 4160511 Carbide Milling Inserts

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | ZZGT Li |

| Certification: | ISO9001:2015 |

| Model Number: | 4160511 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Samples are accepted |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Paper box , Wooden Carton or Customized accepted |

| Delivery Time: | 7-15days |

| Payment Terms: | L/C, D/A, T/T, Western Union, MoneyGram |

| Supply Ability: | 400T/year |

|

Detail Information |

|||

| Material: | Virgin Tungsten Carbide | Grade: | K20 |

|---|---|---|---|

| Surface: | Ground | Application: | Cutting Tools |

| Service: | 24hours | OEM: | Accepted |

| High Light: | 4160511 Carbide Milling Inserts,4130511 Carbide Milling Inserts,P20 Tungsten Carbide Products |

||

Product Description

K20 P20 4130511 4160511 Carbide Milling Inserts

ISO standard K20 P20 4130511 4160511 tungsten carbide milling inserts

A guide to the application of cemented carbide brazed tips:

1. The structure of brazed tips too;s should be tough enough.

2. Cemented carbide tios should be strongly fixed securely

3. Before welding of the tips to tool holders, a check must be done on the tips.

4. There are requirements for the welding materials.

5. There are requirements to the flux in the welding process

Grade Performance

| Tungsten Carbide Cold Forging/heading Dies | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| GT55 | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |

More Details:

![]()

Factory Equipments:

There are some advanced producing equipments in Zhuzhou Gingte Cemented Carbide Co.,ltd

* HIP sintering furnace

* Spraying Draying system

* 200T TPA acutomatic press machine

* CNC Grinder

* Spark Erosion machine

* Wire cutting machine,etc

![]()

Contacts:

For further question, pls contact our sales engineer

Name:Daisy Tian

E-mail: zzgt3@gtcarbide.com

Whatsapp/Mobile:+8613874120766