Polished H6 Dia12x75 Solid Carbide Rod , Tungsten Carbide Bar For Cutting Tools

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | Gingte Li |

| Certification: | ISO9001:2015 |

| Model Number: | Φ12*75 |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiable |

|---|---|

| Price: | negotiable |

| Packaging Details: | First paper packing each piece then pack into paper boxes or plastic box,next use exported cartons or wooden cases,or packed as |

| Delivery Time: | 7-15 work days |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 400 tons/year |

|

Detail Information |

|||

| Material: | Contains 100% Virgin Tungsten And Cobalt | Quality: | High Strength High Hardness High Toughness |

|---|---|---|---|

| Service: | 24-hour Online After-sale Service | Technology: | HIP Sintering And Adopt Advanced Automatic Extrusion Equipment |

| Size: | Various Size And Grade For Choose | Packaging: | Standard Export Packing,or Per Customer Needs |

| High Light: | tungsten carbide bar,solid carbide rod |

||

Product Description

1. Grade: YL10.2,YG10X,YG12X,YG15,YG20,YG10,YG8,YG8 etc.

2. diameter from 0.3mm~70mm,

3. length from 10mm~1000mm

4. tolerance for diameter (.-0.05~+0.05),tolerance for length (0~+0.2mm).

5. also can make angles of tips are 30º,60º,90º

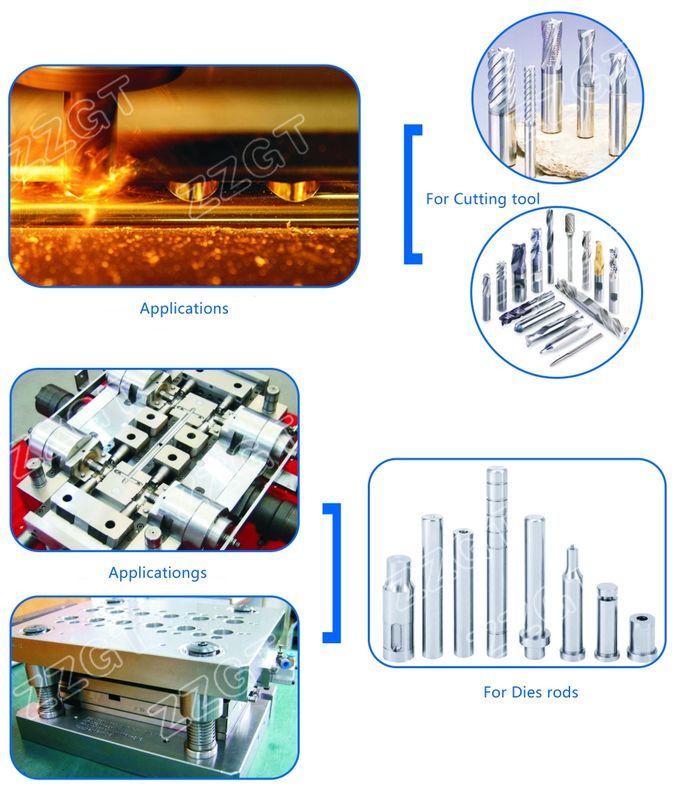

Application:

Rods Grade and performance for Cutting Tools

|

Grade |

ISO Grade |

WC% | CO% |

(µm) |

g/cm3 |

HRA |

HRC |

HV |

N/mm2 |

Applications Recommended |

| GF6X | K10 | 94 | 6 | 0.8 | 14.9 | 91.5 | 78.4 | 1600 | >3200 | Suitable for steel cast iron,alloy cast iron , refractory steel ,alloy steel |

| GF8X | K10-K20 | 92 | 8 | 0.8 | 14.7 | 90.5 | 77 | 1500 | >3450 | Suitable for glass firber reinforced plastics ,titanium etc and low speed cutting |

| GF10X | K10-K20 | 90 | 10 | 0.8 | 14.4 | 90 | 75.9 | 1430 | >3650 | Suitable for cast iron ,non-ferrous metals,hard wood ,common wood etc |

| GF10A | K30 | 88 | 10 | 0.6 | 14.4 | 91.8 | 79.3 | 1650 | >3850 | With hig temperature hardness, widely used in PCB micror drills .For making drills, end mill reamer , taps,burrs etc. |

| GF12A | K40 | 86 | 12 | 0.6 | 14.2 | 91 | 77.7 | 1560 | >4000 | With high temperature hardness, for making drills ,end mill ,reamer ,taps , burrs etc. |

| Product Name | Tungsten Carbide Rod |

| Material | cemented carbide |

| Size | φ12*75 or others available |

| Size Tolerance | h6 or as customer's request |

| Color | As picture |

| Recommend Grade | GF6X etc |

| Grain Size | Fine Grain,Middle Grain size |

| Application | for cutting tool |

| Processing Treatment | Clean ground and polished or as customer request. |

| Product Features | Long life,good wear resistance and high hardness. |

| Certification | ISO9001 |

Grade Performances:

Carbide Rods Grades for Moulds

| Grade | ISO Grade | WC % | CO % | Grain Size | Density | Hardness | T.R.S | Applications | ||

| (μm) | g/cm3 | HRA | HRC | HV | N/mm² | |||||

| GF8 | K30 | 92 | 8 | 1.6 | 14.7 | 90 | 75.9 | 1400 | ≥3500 | Suitable for machining cast iron,aluminum alloy,quenched steels,brass etc,widely used in PCB micro drill and milling tools. |

| GF20 | K40 | 80 | 20 | 1.2 | 13.7 | 84.5 | 66 | 900 | ≥4200 | High strength,mainly used for stamping tool can withstand great pressure. |

Carbide Rods Grades for Cutting Tools

| Grade | ISO Grade | WC % | CO % | Grain Size | Density | Hardness | T.R.S | Applications | ||

| (μm) | g/cm3 | HRA | HRC | HV | N/mm² | |||||

| GF6X | K10 | 94 | 6 | 0.8 | 14.9 | 91.5 | 78.4 | 1600 | ≥3200 | Suitable for steel cast iron,alloy cast iron,refractory steel,alloy steel. |

| YL10.2 | K30 | 88 | 10 | 0.6 | 14.4 | 91.5 | 79.3 | 1650 | ≥3850 | With high temperature hardness,widely used in PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

Size Options:

| Type | OD(MM) | L(MM) | Un-ground tolerance | Fine ground tolerance | |

| φ1~φ4×L | 1~4 | 38.5 50 100 330 | -0.00/+0.30 | -0.00+L×1% | h6 |

| φ5~φ40×L | 5~40 | 100 310 330 | -0.00/+0.6 | ||

For any other sizes we are able to custom-made according to clients’ requirements or drawings.

Product Display and Advantages:

Packing Process:

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.