Wear Resistance Solid Tungsten Carbide Rod Blanks No Pore Pressure Sintering Type

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China |

| Brand Name: | Gingte Li |

| Certification: | ISO9001:2015 |

| Model Number: | 8*310 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10KGs |

|---|---|

| Price: | negotiable |

| Packaging Details: | First paper packing each piece then pack into paper boxes or plastic box,next use exported cartons or wooden cases,or packed as |

| Delivery Time: | 7-15 work days |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 400 tons/year |

|

Detail Information |

|||

| Material: | Contains 100% Virgin Tungsten And Cobalt | Size: | Various Size And Grade For Choose |

|---|---|---|---|

| Service: | 24-hour Online After-sale Service | Technology: | HIP Sintering And Adopt Advanced Automatic Extrusion Equipment |

| Quality: | High Strength High Hardness High Toughness | Packaging: | Standard Export Packing,or Per Customer Needs |

| High Light: | cemented carbide rods,solid carbide rod |

||

Product Description

Product Advantage :

- Good wear resistance

- Good corrosion resistance

- High toughness

- Extrusion method and HIP sintered

- Made from 100% virgin raw material

- Producted with advance equipments and process

- All products go through in-process and final inspection

- Stable and continuous production ability

- All carbide rods are made from the best tungsten carbide powders. The carbide rods are with submicron and average grain size ,the powder is even and stick together firmly,the purity of tungsten carbide powders is quite high.

- All carbide rods are made by the extrusion machine which insure that the inside structure of carbide rods is excellent and apprerance of carbide rods if better ,the flatness is improved a lot .

- All carbide rods are through HIP sintering which insure that the inside structure of carbide rods is free pore and can stick together firmly .Also the TRS is improved around 30% after HIP sintering.

- large stock of regular sizes of carbide rods ,which can enable us to make the delivery within 24 hours.

- Replacement .we will replace the carbide rods for you if there is any defects.

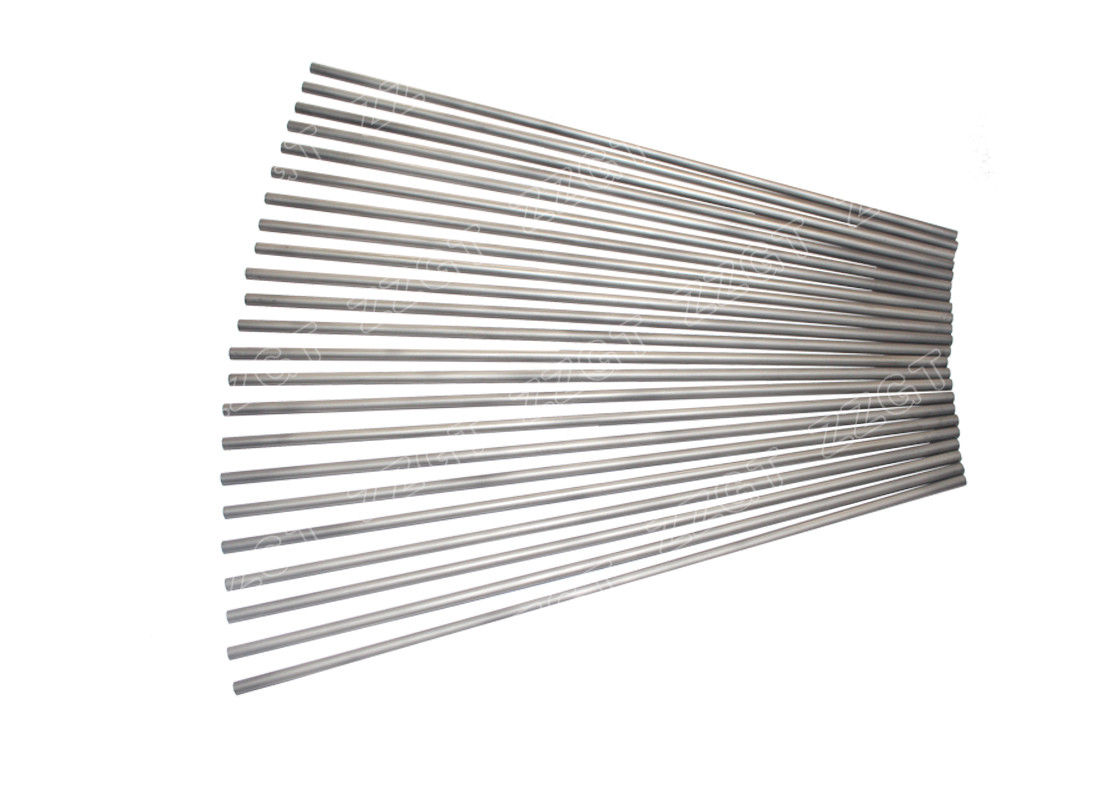

| Product Name | Tungsten Carbide round rods |

| Material | cemented carbide |

| Size | φ8*310 or others available |

| Size Tolerance | blank or as customer's request |

| Color | As picture |

| Recommend Grade | K40 etc |

| Grain Size | Medium Grain |

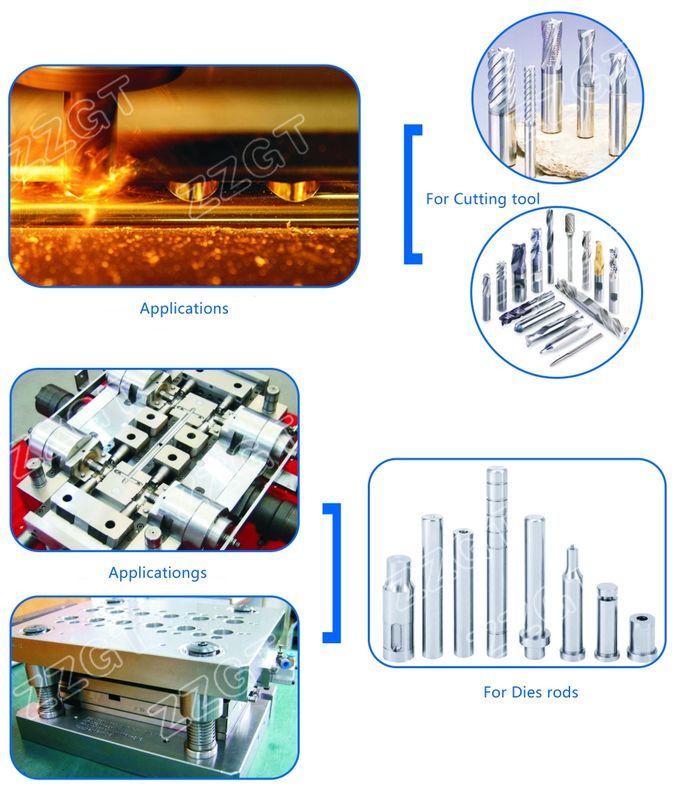

| Application | for Dies rods |

| Processing Treatment | Clean ground and polished or as customer request. |

| Product Features | Long life,good wear resistance and high hardness. |

| Certification | ISO9001 |

Grade Performances:

Carbide Rods Grades for Moulds

| Grade | ISO Grade | WC % | CO % | Grain Size | Density | Hardness | T.R.S | Applications | ||

| (μm) | g/cm3 | HRA | HRC | HV | N/mm² | |||||

| GF8 | K30 | 92 | 8 | 1.6 | 14.7 | 90 | 75.9 | 1400 | ≥3500 | Suitable for machining cast iron,aluminum alloy,quenched steels,brass etc,widely used in PCB micro drill and milling tools. |

| GF20 | K40 | 80 | 20 | 1.2 | 13.7 | 84.5 | 66 | 900 | ≥4200 | High strength,mainly used for stamping tool can withstand great pressure. |

Carbide Rods Grades for Cutting Tools

| Grade | ISO Grade | WC % | CO % | Grain Size | Density | Hardness | T.R.S | Applications | ||

| (μm) | g/cm3 | HRA | HRC | HV | N/mm² | |||||

| GF6X | K10 | 94 | 6 | 0.8 | 14.9 | 91.5 | 78.4 | 1600 | ≥3200 | Suitable for steel cast iron,alloy cast iron,refractory steel,alloy steel. |

| YL10.2 | K30 | 88 | 10 | 0.6 | 14.4 | 91.5 | 79.3 | 1650 | ≥3850 | With high temperature hardness,widely used in PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

Size Options:

| Type | OD(MM) | L(MM) | Un-ground tolerance | Fine ground tolerance | |

| φ1~φ4×L | 1~4 | 38.5 50 100 330 | -0.00/+0.30 | -0.00+L×1% | h6 |

| φ5~φ40×L | 5~40 | 100 310 330 | -0.00/+0.6 | ||

For any other sizes we are able to custom-made according to clients’ requirements or drawings.

Application:

Packing Process:

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-25 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.